製管機

SF-35

3 Welding Torches

TIG tube mill supply - Sunfone

20+ years of seasoned tube making machine experience

Tube Mills

SF 35 - TIG Welding tube mill built for high standard buyer

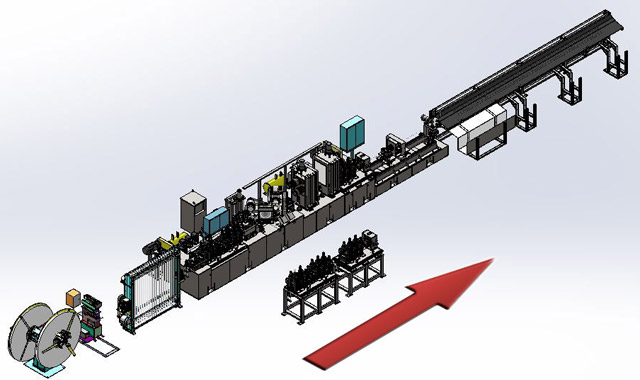

SF35 is a TIG Tube Mill built for a Japanese buyer with a plant in Thailand. They are TOYOTA's supplier, thus, a quality tube mill to meet their client's high standards was requested. Sunfone is a tube mill manufacturer from Taiwan with 20+ years of seasoned tube making machine experience, which has permitted them to sell worldwide.

SF35 is a custom made tube mill. It contains 3 welding torches, a belt type bead grinding machine and a wheel type bead grinding machine, a burr free roller cutting with quick mold changing function.

There are only 1-2 tube mill companies providing such high-end belt type bead grinding machines in Taiwan. The belt type bead grinding machine is a newly added item to the tube and pie making machine. Rather than just a wheel type bead grinding machine, SF35 is equipped with both belt and wheel type bead grinding machines. It can achieve client's strict tube roundness and surface standards. SF35 belt type bead grinding machine's bracket is designed based on an Italian machine. As you can see from the video, the cradle's swing range is wide and its automatic belt height adjustment ensures precise grinding performance.

SF35 has three welding torches and mounting brackets to operate short distance weldings. Each torch's holder is built solidly without shaking. Burr Free Roller Cutting is one of the advantages of SF35. When using roller cutting, the burrs curl inside instead of outside to avoid cutting. The cutting range is broad, between 100mm - 6m, and the cutting tolerance is 0.5mm.

SF35 uses PLC control, a SUMITOMO motor and a SUMITOMO hydraulic transmission box, etc.

SF35 TIG tube and pipe making line:

1. Uncoiler

2. Shearing and weldering

3. Hoop cage (stainless steel pipe to avoid damage of belt)

4. Forming section

5. Welding section

6. Belt and wheel type bead grinding machine

7. Sizing section

8. Quick-change system

9. Rolling-cut type of Cut-off machine

10. PLC control system

11. SUMITOMO motor

12. SUMITOMO hydraulic transmission box

- 影片介紹

榮昭科技 製管機服務簡介

榮昭科技有限公司是台灣一家擁有超過23年經驗的專業製管機生產製造服務商. 我們成立於西元2000年, 在製管機,管機,管機配件市場。領域上, 榮昭科技提供專業高品質的製管機製造服務, 榮昭科技 總是可以達成客戶各種品質要求