CNC Cut-to-Length Machine

SF-S420 / SF-S432 / SF-S460 / SF-S520 / SF-S532 / SF-S560 / SF-S7120

CNC Cut-to-Length Machine

High Speed computerized numerical control (CNC) plus AC servo drive system technology together with fully automatic hydraulic controlled uncoiler that ensure our CNC Cut-to-Length machine to achieve you tough cutting job for sheet metals with fast speed, greater accuracy improved efficiency, easy operation, reduing manpower.

- Greater cutting accuracy

- Improved Reliability

- Planned production

- Flexible processing alternatives

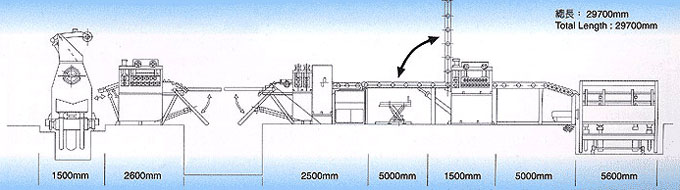

Line Up

- Double side uncoiler

- Rough and Precise Leveler

- Shear machine

- Loop bridge

- Conveyor

- Stacker

- Electric control equipment

Feature

- High speed CNC (Computer Numerical Control) and AC Servo Drive System for better positioning, cutting accuracy, and reliability.

- High-resolution graphic monitor for the plant floor man-machine (MM) message handling and display.

- Programmable function keys for specific tasks.

- Cutting functions can be selected in either auto or manual mode. In auto mode, the system is able to make single step and/or continual operations.

- You are able to set; cutting length, quantity, job number, and parameter adjustment…via the front panel screen.

- A dedicated screen / menu that can be used by the operator for: job numbers, cutting length, quantity, and for setting operational parameters.

| Model | Steel Sheet Thickness (mm) | Steel Sheet Width (mm) | Shearing Length (mm) | Coil Weight (mm) | Space Required(m³) |

|---|---|---|---|---|---|

| SF-S420 | 0.2~2.0 | 600~1230 | 600~2440 | 5~15 | 5x21 |

| SF-S432 | 0.4~3.2 | 600~1230 | 600~3000 | 5~15 | 5x21 |

| SF-S460 | 0.4~0.6 | 600~1230 | 600~3000 | 5~15 | 5x26 |

| SF-S520 | 0.2~2.0 | 600~1560 | 600~3000 | 5~20 | 5x21 |

| SF-S532 | 0.4~3.2 | 600~1560 | 600~3000 | 5~20 | 6x21 |

| SF-S560 | 1.0~6.0 | 600~1560 | 600~6000 | 5~25 | 6x32 |

| SF-S7120 | 3.0~12.0 | 600~2000 | 200~12,000 | 5~25 | 8x45 |

- Movie

- Related Products

Automatic Steel Sheet Slitting Line

SF-160 / SF-180 / SF-220 / SF-250 / SF-280

Sunfone Technology Co., Ltd offer standard models of accurate & precise Uncoil Recoil Slitting...

Details

Designed for uptime, easy upkeep, and clear documentation

This Tube Mill helps you keep production steady while maintaining weld and surface quality.

Sunfone Tech emphasizes accessible maintenance and operator‑friendly adjustments to reduce changeover time.

Tell us your target OD and materials; we’ll outline an approach and comparable installs.

Sunfone Tech invites you to explore our high-quality Tube Mill, End Facing Machine, Tube Polishing Machine. Contact Us for more details!