Quality Slitting Line - 0.2mm-1.5mm Seamless Slitting Machine

SF-160

Accurate and Precise Uncoil Recoil Slitting Line Machine

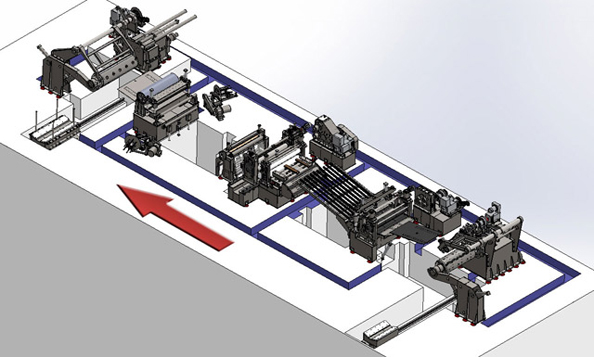

SF 160 Slitting Line was designed for a Japanese company that is specialized in providing coils to various Japanese companies located in Indonesia, and in various industries including automotive, electronic accessories, car accessories, etc. The buyer wished to procure a slitting machine without spending too much money on the base, therefore, Sunfone designed a cost-saving base. Since the coil is used for a lot of zinc plating and PPGI (Prepainted Galvanized Steel), therefore, scratches are not allowed on the surface.

To slit a steel sheet that is 0.2mm thick can be critical. Tension control and buffer bin are implemented at the uncoiler to avoid excess sheet tension. To slit a 0.2mm steel sheet, an extremely accurate slitting knife and spacer are required. The SF 160 slitting machine slits steel sheets between 0.2mm – 1.5mm.

High performance slitting machines designed for a Japanese buyer

SF 160 Slitting Line is equipped with a seamless type recoiler, it curls the steel sheet with round internal diameter without any dents or leftover marks.

1. Single arm uncoiler with tension control and buffer bin

2. Pinch roll and levering machine

3. Cutting machine

4. 1st bridge

5. Pinch roll and Side guide device

6. Slitting knife and spacer

7. 2nd bridge

8. Tension control station

9. Seamless type recoiler

10.Support arm

- Movie

- Related Products

Automatic Steel Sheet Slitting Line

SF-160 / SF-180 / SF-220 / SF-250 / SF-280

Sunfone Technology Co., Ltd offer standard models of accurate & precise Uncoil Recoil Slitting...

DetailsMini Slitter Line

SF-100 / SF-150

There are two model of Mini Steel Sheet Slitter Line. Slitting Speed Max 120m/min with steel...

Details

Build Reliable Tube Production with Sunfone Tech

Scale output without sacrificing quality. Our high‑speed tube mill platforms combine rigid frames, accurate forming, and stable welding to keep your lines running smoothly.

From quick changeover and PLC control to intelligent monitoring, each station is designed to shorten setup time, reduce scrap, and deliver repeatable dimensions for steel and stainless tubes.

Talk with our engineers about sizing, tooling, and upgrades for your application—round, square, or rectangular tubing.